Empowering a sustainable future with green hydrogen

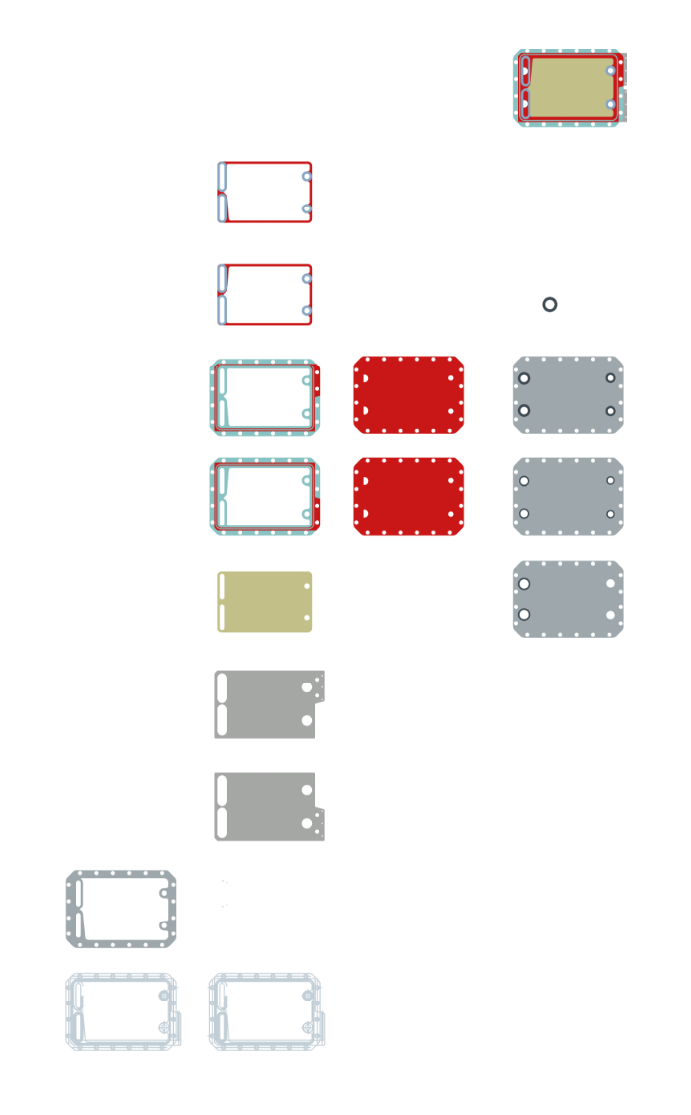

part → assembly → stack

At Neocartesian, we lead the way in innovation, reshaping our clients' journey toward a sustainable business, step by step, part by part. Our mission is to provide our clients with a robust industrial electrolyser design with every part considered and simplified for mass modular production.

Our preliminary stack performance modelling is designed to streamline iteration time and mitigate the project risk associated with underperformance. Several factors of the design are carefully balanced to govern the performance and cost of the stack. These factors include stack geometry, pressure, temperature, optimised electrode form for gas removal, electrode substructures and materials and the use of catalysts to decrease voltage potentials. Once a direction has been determined, the stack is conceptually modelled using advanced FEM analysis, ensuring the stack complies with PED or ASME BPV type approval. Neocartesian’s team includes engineers are trained in CFD modelling, ensuring that gas removal from the stack is efficient and that electrical conductivity is effective throughout the stack's axis and reducing gas crossover and losses due to shunt currents.

Neocartesian is one of the few engineering companies to design and construct electrically insulated stacks conforming to ATEX Zone 2 compliance. Stacks are connected via junction boxes, and the need for protective covers around the entire stack is removed, minimising the risk of electrocution and short circuits.

The stack health and performance is determined by monitoring the voltage potential of each cell. This can be accomplished through a dedicated monitoring system or periodic checks.

stack validation

It can be expensive to design and build a complete stack only to find out that you have a gas leak between the oxygen to hydrogen cells, or that the conductivity of the electrode substructure corrodes after 5 cycles, or that gas bubbles block passages, reducing the wetted surface area of the electrode. All needs to be verified first! Therefore, Neocartesian builds stacks with the confidence of confirmation that everything works as it should. Test rigs and short stacks are designed by and manufactured by Neocartesian before the final stack is built in its entirety. Our clients can refine the design within fixed geometry and parameters before the stack design is finalised. These facilities are continuously used to provide incremental improvements beyond the finalisation of the stack, improving future stacks and R&D..

quality is paramount

Once the design is complete, Neocartesian is not finished… Stacks can contain more than 250 cells per stack, with thousands of parts. Therefore, it is essential that every part and subassembly are tested before being placed into the final assembly. A QA system for parts and assemblies with a pass rate of 99,9% is far from acceptable, resulting in 1 out of 2 stacks built being disassembled after testing. A heavy cost to pay. Hence, Neocartesian has assisted in the design of test facilities and procedures to ensure that all components are thoroughly tested and QA-certified.

Neocartesian has multiple partners in the industry to supply key components, for both testing and full scale manufacturing.

stack → product

Neocartesian has decades of experience in ammonia processes, including the production of hydrogen. It brings this industrial knowledge to provide to clients a complete engineering solution.

This includes containerised or industrially housed units including the following equipment

- Power management system

- Switchgear and transformers

- Separators and scrubbers

- Hydrogen gas purification

- De OXO

- PSA and TSA

- Gas compression

- Deminerialised water skids

- Cold Vent stack

- Downstream production plants (ammonia, methanol and formic acid)

safety first

Neocartesian works on its own process engineering methodologies that incorporate several industrial codes and standards. These include the following

- HAZID study

- QRA study

- HAZOP study

- LOPA analysis

- SIL analysis & classification

- safety distance calculations of a hydrogen jet fire

- Radiation levels from a cold stack or flare

- ATEX zoning

Neocartesian has the capability to link electrolysers directly to the DC source, eliminating the need and cost of an AC/DC for both solar panels and electrolyser. This represents a savings of approximately one-third of the total capital expenditure.